|

|

Specifications of Indoor multi-purpose optical fiber

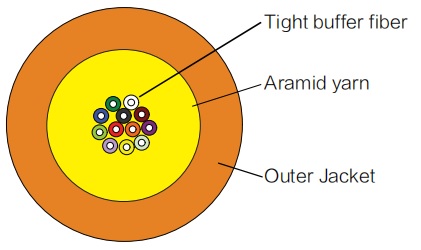

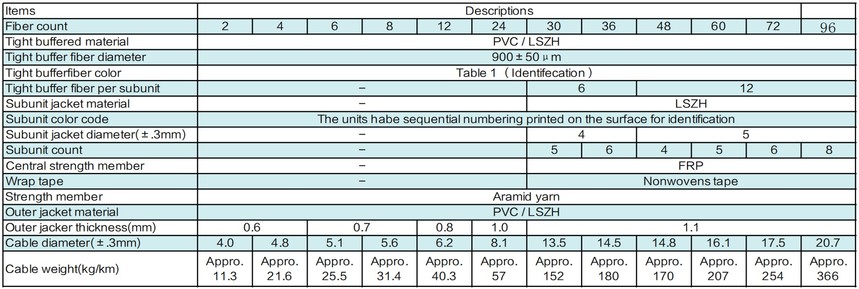

Product advantages - Fastlinkcabsys single unit indoor non-metallic optical cables use 900μM flame retardant (tight buffer) optical fiber is used as the transmission medium, the outer coating is polyvinyl chloride (PVC) or low smoke halogen-free (LSOH), and the outer coating is filled with aramid yarn to provide better protection and tensile resistance of the optical cable; The maximum number of cores of optical fiber is 96. - The overall structure of fastlinkcabsys single bundle indoor optical cable is free of metal materials and easy to peel except for coating, and conforms to RoHS 2011/65/eu environmental protection specifications and standards. - Optical fiber test standard basis: IEC 60793-1-xx:2002 and en 60793-1-xx:2002. Product structure characteristics 2~96 core multi casing Tightly sheathed optical fiber diameter: 900μm Optical cable diameter: 4.0~20.7mm Weight of optical cable: 16~366kg/km Bending radius (IEC 60794-1-2-E11): 20 x optical cable diameter (during installation) 10 x optical cable diameter (during operation) Tensile strength (IEC 60794-1-2-E1): 02 ~ 12C: 130N (during operation) 440N (during installation) 14 ~ 24C: 200N (during operation) 660N (during installation) 30 ~ 96c: 400N (during operation) 1320N (during installation) Compressive strength (IEC 60794-1-2-E3): 1000N/100mm Impact force (IEC 60794-1-2-E4): 10Nm Torque (IEC 60794-1-2-E7): 5 cycles ± 1 turn Flame retardant polyethylene (PVC): UL OFN, OFNR or OFNP Flame retardant low smoke halogen-free (LSOH): IEC 60332-1-2、IEC 60754-2 IEC 61034-1、IEC 61034-2 Applicable temperature (IEC 60794-1-2-f1): -20 ~ +60 ℃ (in stock) -20 ~ +60 ℃ (during operation) Tight cover color code arrangement

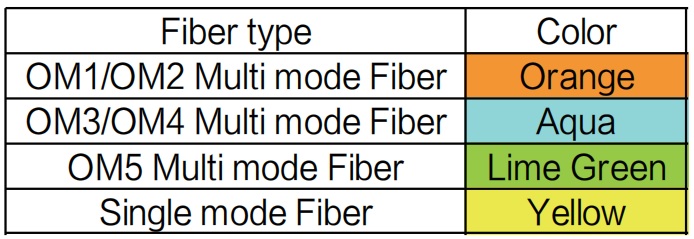

Color difference of optical cable sheath

Optical cable structure size

|